Revolutionizing Dentistry: The advancements in Dental 3D Printing Technologies

3D printing, also known as additive manufacturing, was first introduced in the early 1980s by Charles Hull, who is considered one of the pioneers of the 3D printing industry. Charles Hull invented 3D printers using stereolithography (SLA), a technique currently being used by a number of 3D printer manufacturers. 3D printing is a method of producing 3-dimensional objects layer-by-layer using computer-aided design. Given its ability to print complex models using a wide range of materials, 3D printing has applications across various industries, including dental, aerospace, automotive, healthcare, food, fashion, mechanical engineering and other manufacturing industries. In recent years, the adoption of 3D printers has risen at a commendable pace, specifically in the dental industry, attributing to the extensive growth in the digital dentistry business and rise in the demand for 3D printed products, including dental restorations, orthodontic models, dentures, aligners, crowns, retainers, bridges, as well as surgical guides.

Moreover, dental 3D printing has showcased the ability to overcome several challenges associated with the conventional dental product manufacturing methods, including poor quality and accuracy of dental products, time-consuming printing processes and high cost of dental products. Dental 3D printing offers more treatment choices for both patients and clinicians at reasonable prices, while increasing productivity, quality of care, and enhancing the overall customer experience in the dental industry. Further, since 3D printing is a digitalized process, the products manufactured using this technology are customizable (even the complex dental structures), offering more precise and accurate solutions for dental applications. The dental 3D printing market is estimated to be USD 2.9 billion in 2023 and is anticipated to grow at an annualized growth rate (CAGR) of 15.1% during the forecast period 2023-2035. Driven by the growing prevalence of dental diseases and rising demand for high quality dental products, the dental 3D printing market is expected to witness a steady growth during the forecast period.

Process of Dental 3D Printing

Dental 3D printing is a simple process that includes four to five steps for manufacturing desired dental products. It starts with the collection of data with the help of a scanner. The collected information (related to the specifications of a dental product to be printed) is then transferred to the computer-aided design and manufacturing (CAD / CAM) software, where customization of the product is done as per the need. The software is further connected to printers, and with a single command, desired dental products are printed using the dental 3D printer.

Dental 3D Printing Technologies

Dental 3D printing employs various types of additive manufacturing technologies to print multiple types of dental products; these include vat polymerization, polyjet, material extrusion and power bed fusion technologies.

- Vat Polymerization: This technology manufactures dental 3D printed products using photopolymerization and molds the photopolymers into solids with the help of UV light. Further, all the resin-based 3D printing methods wherein liquid photopolymer resins are stored in vat, collectively encompass vat polymerization. Vat polymerization technology is further classified into the following subcategories:

- Stereolithography (SLA) technology

- Digital light processing (DLP) technology

- Liquid-crystal display (LCD) technology

- Continuous digital light processing (CDLP) technology

- Polyjet: It is a 3D printing technology that produces 3D dental products by jetting photopolymer materials onto a build platform and solidifying them with the help of UV light immediately after being jetted. Polyjet technology is further classified into the following subcategories:

- Drop on demand (DOD) technology

- Nanoparticle jetting (NPJ) technology

- Material jetting and binder jetting technology

- Material Extrusion: It is a 3D printing technique in which a computer controlled moving nozzle, often abbreviated as an extruder, pours the heated liquid material onto a 3D printing platform, layer by layer. After cooling, the material gets deposited and forms the desired products. Material extrusion technology further consists of Fused Deposition Modeling (FDM) as a subcategory.

- Powder Bed Fusion: It is a 3D printing technology in which powder particles are fused with a heat source, mainly an electron or laser beam, layer by layer until the desired product is obtained. Powder bed fusion technology is further classified into the following subcategories:

- Selective Laser Melting (SLM) technology

- Selective Laser Sintering (SLS) technology

- Direct Metal Printing (DMP)

Applications of 3D Printing in Dental Industry

3D printing is emerging as a crucial technology in the dental industry, for both chair-side and off-site dental printing. Dental 3D printing has offered numerous benefits to dental professionals, as well as patients by providing more effective and affordable dental solutions. Various dental laboratories and dental clinics employ 3D printers for a wide range of applications; these are described below:

- Orthodontics: It is a branch of dentistry focused on the diagnosis, prevention, management, and correction of misaligned teeth and jaws 3D printing is widely used to improve orthodontic practices by producing various types of orthodontic models, with enhanced accuracy. Further, dental professionals utilize 3D printing to accelerate turnaround timelines and produce affordable orthodontic products, including aligners, braces, brackets, retainers, splints and mouth guards.

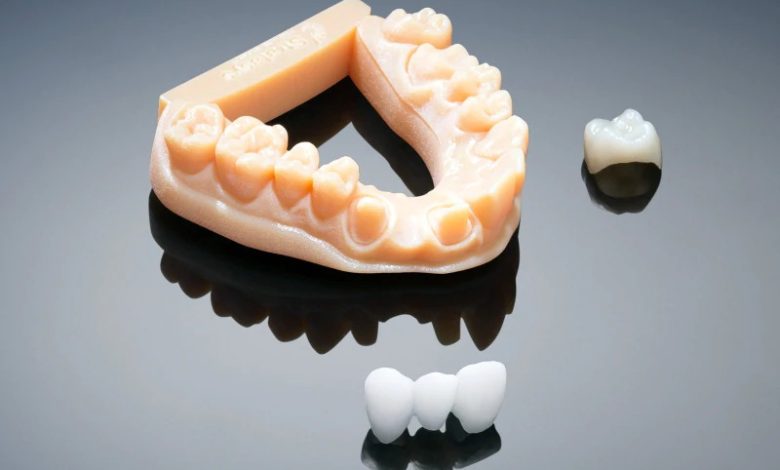

- Prosthodontics: Prosthodontics, also known as dental prosthetics or prosthetic dentistry, is a branch of dentistry that deals with the development and implantation / replacement of a diseased, missing or injured teeth with prosthetic substitutes. Dental 3D printers can be used to produce several types of fixed and removable prosthodontic products, including crowns, bridges, dentures and dental models.

- Dental Implants: A dental implant is an artificial device, made of titanium, titanium alloys or ceramics, that acts as a substitute / support for the artificial teeth or root of a tooth and is generally available in the shape of a screw or cylinder, embedded into the jaw. A successful dental implant offers stable and rigid support for the retention or support of a bridge, denture or other prosthetic devices. Products, such as implants and surgical guides can be produced using dental 3D printers.

Future Perspectives

Given the continuous technological advancements, 3D printing technology has proven to be a disruptive technology, challenging traditional manufacturing approaches used in various industrial sectors. Having been historically used in the aerospace, defense, art and design sectors, 3D printing is becoming a subject of great interest in the dental industry. 3D printing in dentistry enables the use of several additive manufacturing techniques to provide better workflows and more satisfying clinical results. Further, digital dentistry aims at providing highly accurate in-house (same day) printing.[1] Driven by several factors, including the increasing incidence of dental caries and other dental diseases, challenges associated with conventional methods of dental product manufacturing, and rising demand for cosmetic dentistry, the dental 3D printing market is anticipated to witness steady growth in the foreseen future.

About Roots Analysis

Roots Analysis is a global leader in the pharma / biotech market research. Having worked with over 750 clients worldwide, including Fortune 500 companies, start-ups, academia, venture capitalists and strategic investors for more than a decade, we offer a highly analytical / data-driven perspective to a network of over 450,000 senior industry stakeholders looking for credible market insights. All reports provided by us are structured in a way that enables the reader to develop a thorough perspective on the given subject. Apart from writing reports on identified areas, we provide bespoke research / consulting services dedicated to serve our clients in the best possible way.